The developing world is becoming more industrialised as developed countries continue to thrive with technological innovations. Meanwhile, as risks multiply and evolve, human beings remain vulnerable to various chemical and physical threats.

The need for personalised protective equipment (PPE) has never been more relevant as industries increase in confidence to expand their scope beyond known boundaries.

The risks of doing dirty work

Human beings are not made of stone. Even though we have the confidence to work in exposed and challenging environments, we cannot overlook the fact that skin breaks and burns, and that bones crush under intense pressure.

Fortunately, available solutions are offering adequate protection to workers who do the “dirty work,” so to speak. Flame hazards can be addressed, and abrasion protection is evolving to accommodate different types of endangerment.

Since on-the-job hazards are varied, the roster of available personal protective equipment has broadened to accommodate changing needs.

Worker safety

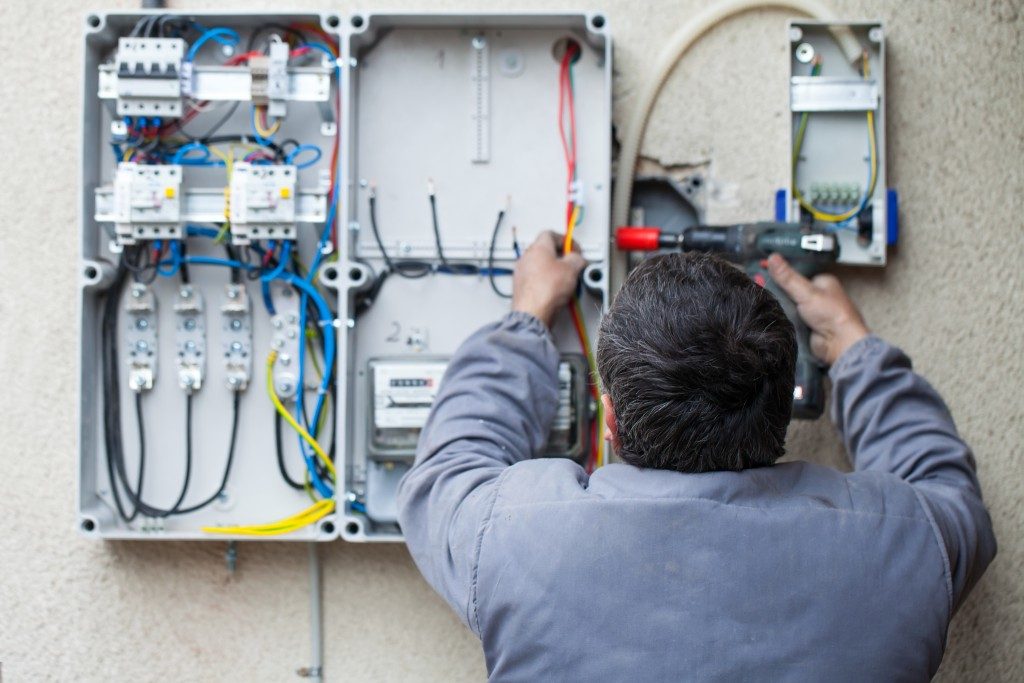

Skilled workers and day labourers alike encounter many safety hazards. From wet floors to heat or cold exposure to falling debris, there are many dangers facing workers as they go about their daily tasks. The absence of proper personal protective equipment, or the failure to wear them contribute to the number of fatalities, and severity of severity following injuries incurred in the workplace.

The primary purpose of PPE is to reduce exposure to hazards while protecting vulnerable body parts. Workers have the right to be protected from environmental conditions that could pose serious harm to their person.

Workers have the right to be given additional protection when administrative and engineering controls are still inadequate in providing an acceptable level of protection.

Work hazards

A worker who is not wearing the appropriate PPE could be hurt by a projectile that breaks the skin or blinds the eyes. Some workers could suffer from severe chemical burns if the material they are using to protect the hands is not explicitly designed for use in handling the substance.

A worker who is not given proper orientation on safety hazards could be electrocuted while handling critical equipment.

Essential personal protective equipment

Eye protection, safety helmets, harnesses and respirators are some of the basic examples of personal protective equipment. It is not enough that these products are made available to workers. A worker should receive the right type of PPE, and all his or her needs must be answered.

Moreover, the employer should provide additional training, when required. Some types of PPE can only be used effectively when the user is trained appropriately by a certified body.

Without personal protective equipment such as safety glasses for the eyes or flame-retardant clothing, a worker will be exposed to harmful agents. Some of the agents could cause physical injury, while others could affect cellular function and result in debilitating illness.

Some work environments are incredibly challenging and put workers at harm’s way. With the right type of personal protective equipment, exposure to hazards can be reduced significantly. Every worker has the right to receive protection from these hazards.

Always wear prescribed safety equipment, observe regulations when handling potentially harmful substances, and report any work hazards that could jeopardise your health and wellbeing.